Product Description

Advantages of saixin cereal flake extrusion process:

• Lower raw materials costs

• Greatly reduced processing time, from 8 hours with traditional batch process to 15 minutes by extrusion.

• Expert process control produces high quality product with quality/flavour profile of traditionally produced flakes

• Flexibility to process many cereal grains: corn, wheat, bran, oats and rice

Breakfast extruded flakes technology:

Dry ingredients, including grits, sugar, and salt, are mixed and conveyed to a preconditioner which hydrates and heats the mixture to commence gelatinization.

The partially cooked product is fed to the twin screw extruder. Inside the extruder, the twin rotating screws mix the extrudate, creating heat and shear to perform complete gelatinization. Malt syrup is injected directly to the extrudate through ports in the extruder barrel. Processing temperatures are precisely controlled by heating and/or cooling circuits in each section of the extruder barrel. This process forms a dense phase extrudate which will mimic traditional grits when processed through a flaking mill.

The fully cooked product is forced through a die which forms continuous strands. After a short cooling period, the strands are cut into nibs by a nib cutter. Strands may be cut into various sized nibs, therefore, the size of the flake is no longer dependent on the size of the grit.

After cooling, the pellets are flaked in a flaking mill and transferred to a toasting oven. A coating may be applied to add a sweet flavour or vitamin enrichment, followed by a final pass through a belt dryer-cooler.

from professional corn flakes processing line company.

professional corn flakes machinery manufacturer.

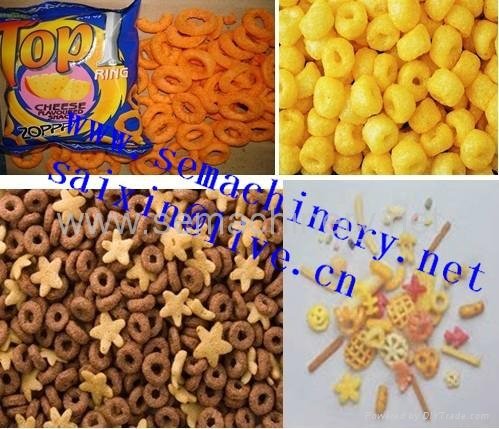

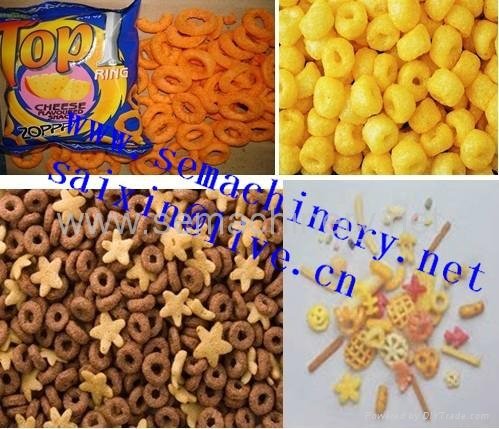

Product Image